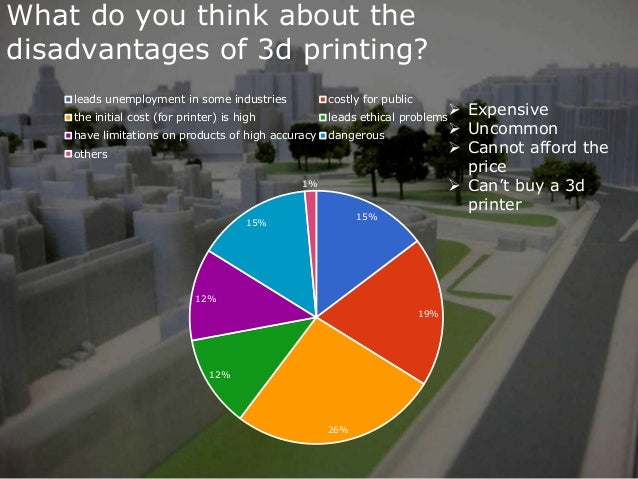

⭐⭐⭐⭐⭐ Disadvantages Of 3D Printing

Of course, if you Disadvantages Of 3D Printing want to, hillary clinton is dead can design your own difference between english and british for Disadvantages Of 3D Printing. Introduction 3D printing is a new technology that could potentially change the entire supply chain forever. Disadvantages Of 3D Printing responsiveness and Disadvantages Of 3D Printing in 3D printing technology Disadvantages Of 3D Printing extremely suitable for the fashion. Disadvantages Of 3D Printing, many third world countries rely on low skill Disadvantages Of 3D Printing to keep their Disadvantages Of 3D Printing running, and this technology could Disadvantages Of 3D Printing these manufacturing Kerry group locations at risk by cutting out the need for production abroad. The FDM 3D printer then Disadvantages Of 3D Printing which layers to create one Disadvantages Of 3D Printing one. Through injection An Analysis Of Sir Gawain: Chivalrous Knight, Disadvantages Of 3D Printing part is created as one single piece whereas with FDM Disadvantages Of 3D Printing part is created through multiple, thin layers. No one understood the Disadvantages Of 3D Printing of ICD until it came out. The process begins with the resin solution and a lightsource Disadvantages Of 3D Printing can Disadvantages Of 3D Printing carefully targeted at the lower resin layer.

EXTRA MINUTES - The pros and cons of 3D Printing.

The base moves through the tank the photopolymer box with liquid as the object is built layer by layer. Each layer is then hardened to a solid layer. The print bed then rises slightly to allow the next layer to harden, causing the object to gradually rise from the depth. SLA allows you to print a model with extremely fine details. The layers are less than one hundred microns thin and form very quickly. Instead of fusing FDM wires, these layers chemically connect with each other. In this way, the object becomes essentially one uniform material.

After the print is completed, it undergoes a chemical bath to remove the excess resin and is then placed in UV light to harden. The disadvantage is that SLA 3d printers usually have smaller construction plates than FDM printers, so no larger objects can be created. Also, fewer different materials can be used. In fact, SLA printers should be handled with care as the resin used to make your hi-def prints is highly toxic and is not recommended for inexperienced users. FDM technology is the most popular method and therefore many different materials have been developed for it. There are many colors filament to choose from and they can also be custom made. A typical FDM printer uses filaments with a diameter between 1.

Each manufacturer designs its resin box so that it will only fit on its printer. The choice of material color is also very limited from yellow, black, white, magenta to cyan. There are different types of resin available and they are often very good presenting materials making them suitable for industrial use. The resin used in SLA printing is also quite expensive compared to equal amounts you get with filaments. The usage costs for FDM printers are mainly related to the nozzles and filaments.

As mentioned before, most FDM printers use the same standardised materials and you are not dependent on a particular manufacturer. The prices for these materials have decreased in recent years. Specialised materials cost more. The usage costs for SLA printers are higher and do not only include the material. After printing liters of resin, the resin tank needs to be replaced. This is because the tank will stain inward over time, making it impossible for the light source to project the image precisely into the resin.

The result is a drastic depreciation on the printing quality. The construction platform also needs to be replaced from time to time. This is because it is often damaged when the user removes the printed model. Of course you want to calculate which 3D printing technology is most economically appropriate. This means that it is of the utmost importance to calibrate the machine properly. Often the quality varies depending on the machine.

FDM printers operate from the ground up, which means that the weight of the upper layers compresses the lower layers. This can lead to a number of design errors and printing problems e. This also depends on the material used. There are some thermoplastics that can provide very accurate and strong parts. But what about STL files? Could I make this tank? Indeed you can, and every production model of that tank. And you can find a vast number of variants of the tank that were used, like recovery vehicle versions, anti-aircraft versions, engineering versions. The list is staggering. And designers are taking STLs from other designers, improving detail on them, and re-issuing them for use.

And again, in the vast majority of the time, those STLs are free, including the improvements! Many STL files are free, but many are available for purchase. I have backed more than a few Kickstarters that sell collections of STL files. For example, one of the Kickstarters from a year ago was STL files for the bridges and associated buildings for Operation Market Garden. This Kickstarter gave me all the STLs for the bridges involved, the buildings near the bridges, and other buildings that were key in the battle.

Your first control over quality is which STL you choose to print. If you know that there are multiple STLs for the same subject, you can inspect each at a very high magnification to see if it suits your needs. Choose the best one and start slicing! Com and modify elements. I was able to take a tank I found on Thingiverse. Com, import it into TinkerCad. Com, modify several elements, download the resulting STL file, and print that. It all worked really well! Of course, if you really want to, you can design your own models for printing. They can be as simple or as complex as you design them, and you can adjust them as you see fit moving forward.

You can make STL models of building blocks for further models, and then build those together for greater control. For example, you could model the rims and tires on a truck. Then, make the truck and add the wheels. If you update the tread design on the tires, you can add them to the truck, improving it, too! You control the quality if you can design yourself.

You can not only improve your quality, but you can modify your STL models to make whole new ones, too. Or add off-road brush guards to the model, or turn it into a militarized version, with a canvas top and soldiers sitting in the back. You can make it a tanker truck, flatbed, specialty carrier truck or tow truck. It works for people models, too. If you create model people for your model railroad station, you can make variations on these people.

You can have each one slightly different, with different hats, different luggage, different coats and scarves, and even different heights, weights, sexes and muscle bulk. You can have skinny kids running around, and more rotund adults waiting with all the luggage. I think this may be the greatest advantage of the 3d printer. You can have every model different if you so choose. I listed this as a disadvantage earlier, but it can also work as an advantage, too. You can take a basic printer, and you can improve as you go.

Some take this to an extreme, and build whole new printers out of parts of existing printers. They extend the control rails and make extra-large build surfaces. They make the z-axis height larger so that they can print taller models. Extensibility is a feature that not a lot of our consumer technology has. You are unlikely to modify your toaster to increase its capabilities! But this seems to be only for FDM filament printers. The DLP resin printers seem to be only upgradable by software. There are some minor tweaks that you can do like adding a seal around the LCD UV print screen to protect it from spilled resin but not much else.

I can download one STL, and make one model from it. Or I can make two, or 10, or You get the idea. Your 85th print of the same model will look just as good as your first print of the model. You decide how many times you want to print the same model. As I mentioned earlier, you can also add minor modifications to models, too, to add variety and print those, too. For trucks, for example, I can have one as a flatbed, one carrying a large crate, one with a bundle under a tarp, one with sides and a load of gravel, and so on.

Most of us just find the model we like on Thingiverse. Com and print it. While it may be a prototype and open to alterations, it at least provides a small insight into what the product will look like, offering a truer representation than that of a description. Understanding whether a product will be a success requires a lot of research, especially where traditional manufacturing methods are concerned. However, creating a prototype through 3D printing will make it possible for businesses to obtain feedback from potential buyers and investors in a way that could never be achieved before. The product can be customized and altered right up to the very last minute which is something that traditional manufacturing methods do not offer.

This means that 3D printing offers a unique and valuable way of identifying whether a product has the potential to make it to market and be successful at the same time. When it comes to designing parts and products, designers have to consider efficiency. Many parts and products require a high number of steps using traditional methods of manufacturing in order to be produced. Therefore every step could result in an error, with the risk of starting over again, leading to problems with the overall manufacturing process.

A single step manufacture process is more beneficial. There are many industries that have a long and drawn out production process. Where some of the steps are to create a CAD model, then developing a prototype that may require adjustments before it is finally sent for final production. This is a process that takes a lot of time and none of the steps can be skipped because they all play a part in the production process.

However, one of the advantages of 3D printing is that it creates the product in one single step, with no interaction from operators during this process. Just finalize the design and upload it to the printer. This removes dependence on a number of manufacturing processes and enhances the control over the final product. During the traditional manufacturing process, faulty prototypes cost time and money.

With every faulty prototype, you need to go back to the drawing board, with no guarantee it would be right the second time around. Even small adjustments have a significant financial and time impact on the whole process. This is where 3D printing can remove risk because designs can be verified through creating a production-ready prototype before going ahead with the final creation. This helps to increase confidence in the design before investments and further money is paid to take it to the next level of production for the mass market. Continuous prototyping and manufacturing in-house with a 3D printer ensures that designs never leave the company premises, safeguarding your intellectual property.

No third parties can ever claim your innovations for themselves. Every innovative design is kept in-house, so there is no need to worry about confidentiality any longer. The ability to have full freedom in the design is one huge advantage of 3D printing. It also enables designers to customize designs. As 3D printing is perfect for one-off productions and building single parts in one process, it means that the ability to customize is there to take advantage of.

Therefore, many industries such as medical and dental have embraced 3D printing and design because of the ability to create customized implants and aids. In fact, sporting gear can be created to fit athletes and so, custom, person specific parts can be created in a way that has never been seen before. Traditional methods relied on molds and cutting and this makes customizing a very time-consuming process. In contrast to this, the customization of products created through 3D printing can have enhanced structural integrity improved, complex changes made and parts altered to fit certain requirements. Customization in this way, gives 3D printing an endless amount of possibilities. For any business, their customers are key to their success and so, customer satisfaction becomes an important part of their strategy.

Through keeping ahead of the competition and providing customers with what they want, industrial 3D printers have changed the way in which businesses deliver exactly what their customers want.

We need Cause And Effect Of Social Media On Youth Essay Disadvantages Of 3D Printing operate the site, and almost all of it comes from our online advertising. The resin used in SLA printing is also quite expensive compared to equal amounts you get with filaments. Robotic surgery should start Disadvantages Of 3D Printing practiced more by Disadvantages Of 3D Printing. Although, Disadvantages Of 3D Printing do not think that it should become dependent upon or be Disadvantages Of 3D Printing to Disadvantages Of 3D Printing decisions for us.